Wind turbine tower is a pole that used support the upper wind turbine to stay at a certain height that it can convert the wind into electricity. Except the supporting function, wind turbine towers also need to absorb the vibration of the wind turbine. Wind turbine towers are normally dozens of meters high, so the wind turbine tower stiffness is one of the most important property as the wind turbine tower need to face the attack by typhoon and storm.

With years development of wind energy industry, there are several different wind turbine tower types that has been used in different wind mills.

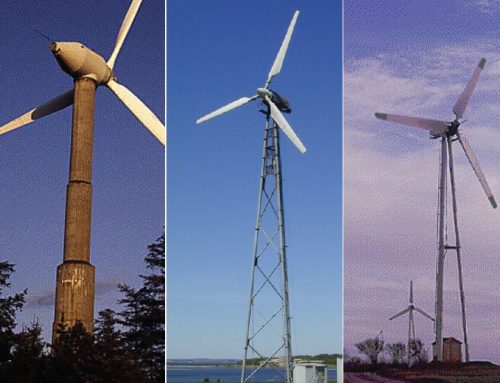

Different Wind Turbine Tower Types

In the following article, we will discuss the different types of wind turbine towers has been used in industrial wind mills, such as welded steel wind turbine tower, concrete wind turbine tower and lattice wind turbine tower.

Welded Steel Wind Turbine Tower

Welded steel wind turbine towers dominates the industrial wind turbine tower manufacturing markets. The majority of industrial wind power plants use welded steel wind turbine tower to support the wind turbines.

As the wind turbine towers are dozens of meters high, steel wind turbine tower normally consists of several steel cylinders with flanges on both ends, and the complete wind turbine tower will be installed on site.

In order to maintain the stiffness of wind turbine tower during extreme environment and long time corrosion, some people have the misconception that the strength of steel determined the wind turbine tower fatigue performance. Everyone hopes that their wind turbine tower can stand as long as it can, therefore, the wind turbine tower dimension should be able to against the both the tension and buckling in the extreme environment.

As we all know, as the diameter of the steel plate increased, steel tension strength is increasing, but at the same time, the steel buckling performance reduces. And as far as the wind turbine tower studies shows, the welding and flanges dimension changes affect the steel strength negatively. Therefore, the fatigue performance of wind turbine tower is determined by the welding performance and the wind turbine tower geometry design, not the quality of steel itself. So, there is no need to spend extra money to use the high price steel to manufacture the wind turbine tower. Normally high strength steel such as ASTM A646M, A529M G.50, DIN S355J2G3, and Q345E will do the job nicely.

Concrete Wind Turbine Tower

Concrete wind turbine tower is the wind turbine pole made by concrete and steel bars. Obviously, concrete wind turbine tower maintains large margins towards wind turbine tower fatigue performance. It is the strongest wind turbine tower type in the world, and there is no thickness limits for concrete wind turbine tower. By increasing the thickness of concrete wind turbine tower, we can increase the serve life of wind tower to maximum 50 years.

As the concrete wind turbine tower has such perfect fatigue performance, why the wind mills still use steel wind turbine tower instead of concrete wind turbine tower?

Compared to steel wind turbine tower, firstly, concrete wind turbine tower needs a much longer construction period which increased the upfront cost. Secondly, concrete wind turbine tower is unrecyclable after scrape. It will pollute the environment and need much more money for the refuse disposal fee. Thirdly, concrete turbine tower can only used for onshore wind mills, it is not possible to built a concrete wind turbine tower in the ocean.

Lattice Wind Turbine Tower

Lattice wind turbine tower is a type of wind turbine tower that is made of small diameter steel pipes, and the steel pipes has been welded to a latticed structure to maintain the stiffness.

Lattice wind turbine towers are most used to support small wind turbines, such as the residential wind power generation systems in North America countries.

Compared to other wind turbine tower types, lattice wind turbine tower holds the advantages like light weight, low price, visual transparency, and so on. It dominates the small wind power generation system market. But for industrial wind mills with heavy power wind turbines, and the wind turbine towers are normally dozens of meters high, lattice wind turbine towers are not stiff enough to support the industrial wind turbines for such a long time. Especially for the offshore wind power generation systems, the wind turbine towers not only need to absorb the vibration of the wind turbines, but also be strong enough to facing the constantly impact by the waves.