CNBM Wind Turbine Tower for Sale

Name: Wind turbine tower

Material: Low alloy High strength carbon steel

Grade: AST Type 7 Gr.50, DIN S355NL, ISO E355E, GB Q345E, or other customized choices.

Dimension: Customized

Anyang Machinery is specialized in providing fully customized steel wind turbine towers for industrial wind power generation system of both onshore and offshore wind application. Our R&D department provides 100% original wind turbine tower designs for both onshore and offshore wind power generator systems based on customers’ requirements.

Wind Turbine Tower Introduction

Wind turbine tower is the pole of the complete wind power generation system. As the wind speed increases with the increase of altitude, wind turbine towers are used to support the upper wind turbines to reach a certain height and absorb the vibration of the wind turbine.

Wind turbine towers are not only steel tubular poles with a certain height so that the wind turbine can operate at the suitable position, it also has to maintain enough intensity and rigidity, to make sure that the wind turbine tower won’t topple and fall during the attack of typhoon and storm.

At present, the majority of the world’s wind turbine generator systems with capacity over 100kW use steel cylinder wind turbine towers or steel conical wind turbine towers. The wind turbine tower material is high quality hot-rolled low alloy high strength steel, and the flanges adopts the integral forging method.

Right now, steel wind turbine tower dominates the wind turbine tower market with its beautiful outlook and stable and safety working performance. The importance of steel wind turbine tower becomes more and more obvious with the increase of the capacity of wind turbine generator system and the increase of wind turbine tower intensity. The wind turbine tower weight is half of the complete wind turbine generator system, and the cost of wind turbine tower is about 15% of the complete wind turbine generator system cost. In order to enhance the vibration reducing performance and stability of the wind turbine tower, a mature engineering team is necessary.

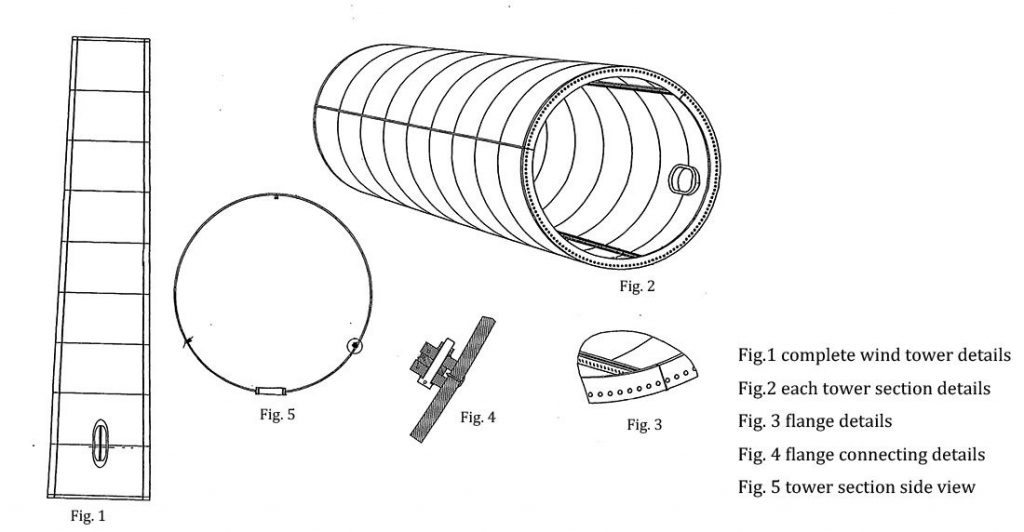

Wind Turbine Tower Structure

Typically, the wind turbine tower height is dozens of meters, therefore, it would be difficult to manufacture a complete steel wind turbine tower with the height of dozens of meters. Moreover, it is also very difficult to transport such a huge wind tower.

Therefore, the engineers divide the wind turbine tower into several steel cylinder sections with the height of 20-30 meters, and there are flanges on both ends of the segmental wind towers.

The segmental wind tower is made of bended steel plates, and both the flanges and the longitudinal joint are welded. After welding, the segmental wind turbine tower will be coated to be corrosion resistance. Then the segmental wind turbine towers will be transported to the construction site, and the segmental wind turbine towers will be bolted to each other on site.

Also, in order to make further operation and maintenance, there are also several wind tower internal components that are welded to the inner side of the wind turbine towers, such as platform, ladder, lift, illumination device and power cables, etc.

Compare Different Wind Turbine Tower Types

Based on the different wind turbine tower materials, the industrial wind mills normally use steel wind turbine towers and concrete wind turbine towers to support the wind turbines. Recently, there is also a new types of wind turbine tower with the lower concrete section and upper steel section.

Therefore, to compare the different types of wind turbine towers can help the customers to choose their suitable wind turbine towers.

Steel Wind Turbine Tower

- Easy transportation & installation

- Mature manufacture technology

- Average price

- Good corrosion resistance performance

- Suitable for both onshore & offshore wind power generator system

Concrete Wind Turbine Tower

- Low price

- No thickness limit of the tower wall

- Long construction period

- The wastes after rejection can’t be disposed

- For onshore wind power generator system only

Concrete and Steel Hybrid Wind Turbine Tower

- Big construction difficulties

- High price for wind turbine tower with the height under 100m.

- Low price for wind turbine tower with the height over 100m.

- For onshore wind power generator system only